Keeping Watch. Ready When Needed.

- Safer deceleration forces for miners (vs conventional safety mechanisms on steel guides) in the event of a rope break or slack rope condition.

- Deceleration rates provided exceed some of the world’s most stringent free fall test requirements.

- Less stressful on the conveyance and shaft guides in an arrestment event.

- Allows for the use of a single-rope hoisting plant with steel shaft guides.

- Tried and trusted technology:

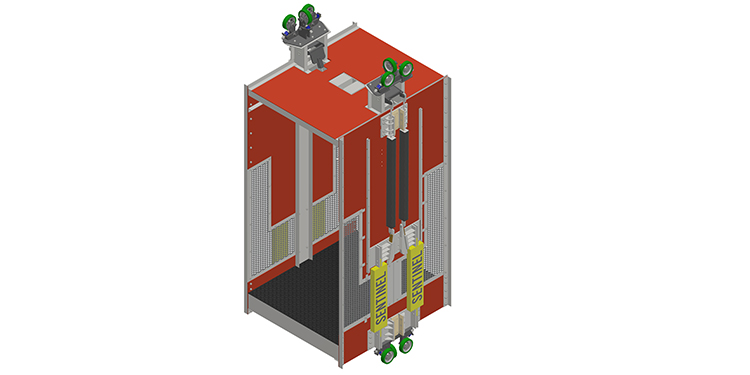

- First stage activation makes use of a conventional drawbar system commonly utilized in mine cages in North America. Spring-activated wedges grip the steel guides, preventing the cage from going into a free fall.

- The second stage provides safe deceleration for the cage occupants through the use of Technogrid® strain energy absorbers.

- Technogrids® are strain energy absorbers and do not rely on friction removing an uncertain variable in wet and dirty mine shafts.

- Designed to deploy when a dynamic incident occurs, Technogrids® used in the Sentinel System are designed to accommodate static loads for required testing.

- Sentinel is a simple, purely mechanical system with few moving parts. The result is a dependable, low-maintenance cage arresting system for use on steel shaft guides.

- Sentinel was developed and is supported in cooperation with FKC-Lake Shore, Technogrid, and Horne Conveyance Safety. The team has more than 230 years combined experience in the design, manufacture, and support of conveyances and conveyance safety products.

TECHNICAL DATA:

| Type | 2-Stage: Wedge & Strain Energy Absorber |

| Deceleration | 0.9–2.0g |

| Application | Steel Guides (HSS, Rail) |

+1 (877) 554-8600 opt. #2